Amazing Chime Projects from Site Visitors!

Sounds of Nature by Anton Petek for the Primary School Lava, Celje, Slovenia. Note the sturdy mounting that allows the chime to be freely supported at the 22.4% location.

Instructor, Mr. Calvin O'Rear, used wind chimes as a DIY wave learning activity for the WAVES section of the physics class. Pictured below are some amazing accomplishments by class members. Note the 3D printing for a few strikers and the additional creativity.

Congratulations!

Sculptures by the Lakes by: Simon Gudgeon from the UK

Simon designed a beautiful monumental wind chime using 76.2mm (3inch) stainless tube with a 3.2mm (0.12598 inch) wall. The design combines sound with kinetics and is held together by tensegrity. It’s installed at Sculpture by the Lakes, my sculpture park in Dorset UK.

www.simongudgeon.com

www.sculpturebythelakes.co.uk

Previous Designs

Chimes on the Beautiful Ohio River by: Jim Donovan

Artwork and murals often adorn the banks of the Ohio River for viewing by passing traffic so Jim Donovan decided to design a chime set for that purpose.

Jim crafted this eight chime set from 3.25" SS. Because the weight from SS tubing is high he gave special attention to support for the tubes and the entire chime set, all made from SS. The wind off the Ohio River can be strong and sustained so a deep concrete base was used for support.

As a fabricator Jim crafted the support pin from SS and Lexan serves as the striker.

Watch the 10s video HERE

Eight chimes with an eight inch diameter and 25 feet long are featured in the spiral staircase at the Ambiente Hotel in Sedona, AZ. The design was perfected in cooperation with Mike Stevenson during construction of the hotel. Special attention was given to the aesthetic finish to be consistent with the environment and landscape of Sedona.

Robust chime set by Robert Goss, July 20, 2023

Robert is very pleased with the sound from his repurposed sailboat booms, one at 4.5" and the second at 5" diameter. The longer chime is 70". The wind sail is from a 1987 Ford Police car. They make an attractive addition to the water front and should easily survive storms.

See them in action HERE (mp4).

Smiles Tell the

Story . . . !

Physics

Class from Nashville Community High School in Nashville, IL –

05/05/23

As the Physics Class finishes their section on waves of all sorts for the

2023 year, the instructor, Mr. Calvin O'Rear, used wind chimes as a hands on DIY

wave learning activity. Pictured* below are some amazing accomplishments by class

members. Congratulations!

*Permission given to post on the internet.

A Wedding

Present for a Good Friend. 05/02/23

Instead of buying another 10 speed blender or pizza stone from the wedding

registry, Stefan decide to do something unique. He made this wedding present chime set from 3/4"

type L copper pipe. An old horse shoe supports the chime set, hung using fishing

line and chain. The final touches involved a heart shaped stone and then

mountains cut from Coors Light cans and set in epoxy for the wind sail. The

stone knocker produced quite the challenge as he found after two hours of trying

to drill it with diamond bits, that it was not possible. He found a way to wrap

the stone in copper thermostat wire and then hang the wind sail off of that. His

friends live in Colorado, so the mountains turn blue when it gets cold out.

Therefore he named it a "Weather Chime."

Traveling Chime Set

by Carol Raedy –

Charlotte, NC 04/09/23

Carol built this fascinating Traveling Chime Set from repurposed tent poles.

Supported by bamboo poles the chimes play Joy to the World when

you walk at a steady pace. Occasionally she will change tunes.

Here is a Happy New Year version.

Space the chimes so when the player walks at a steady pace it plays the song. Each word and dash represents a beat. You can use any length for the beat but it must be consistent. You could begin with one beat = 12 inches and modify from there.

For instance: “Joy” counts as one beat, so you will measure six lengths from where you hang the “joy” bell (Joy plus five beats) and then hang the “to” bell. Measure one length from “to” to “the” and from “the” to “world” since there are no beat between these words. Measure eight lengths from “world” to “all” (world plus 7 more beats) and so. The beats at the end are only if you want to make it in the round.

Carol Raedy graciously provided the following note patterns for each song.

Joy to the World by Hoyt Axton

Joy(E5) _ _ _ _ _ to(D5) the(C5) world(C5) _ _ _ _ _ _ _

All(G5) _ _ _ _ the(E5) boys(F5) and(D5) girls(E5) _ _ now(C5) _ _ _ _

Joy(E5) _ to(G5) the(G5) fish((A5) es(E5)

in(D5) the(C5) deep(Eb5) blue(D5) _ sea(C5) _ _ _

And(G4) joy(E5) _ _ to(C5) you(D5) and(D5) _ me(C5) _ _ _ _ _ _ _ _

Make New Friends

Make(C5) _ new(G4) _ friends(C5) _ _

but(D5) keep(E5) (G5) the(F5) (E5) old(E5) _ (D5) _

One(G5) _ is(G5) _ sil(G5) ver(A5)

and(G5) the(F5) oth(E5) _ er’s(D5) _ gold(C5) _ _ _

Auld Lang Syne

For(A5) _ auld(G5) _ _ (E5) lang(E5) _ (C5) _

syne(D5) _ _ my(C5) dear(D5) _

For(A5) _ auld(G5) _ _ (E5) lang(E5) _ (G5) _ syne(A5) _ _ _ _ _

We’ll(A5) _ take(G5) _ _ a(E5) cup(E5) _ o’(C5) _ Kind(D5) _ _ness(C5) yet(D5) _

For(E5) the(D5) sake(C5) _ _ of(A4) auld(A4) _ lang(G4) _ syne _ _ _ _ _

A Chime Set using the same notes from several octaves

C2-C3-C4-C5-C6 , built by Joey Johnstone. 11/28/2022

Joey used left over items from his plumbing business such as the top support

ring is from the bottom of a propane tank which already had five holes for

hangers. The chime rods are from 1 Inch steel while the striker is a brass apple

and the wind sail is a fabricated brass fan. Joey comments that the striker and

sail are heavy and may need modification to function better in local winds.

Hi-Tech Chimes for Low and High Winds by Lyndon Just

Lyndon wanted a chime set that sounded great in low winds but

would withstand high wind conditions. Using his engineering skills with the CAD

program Solid Works, he designed an innovative solution to achieve both goals.

Read about the design and building process

HERE. See the video

HERE

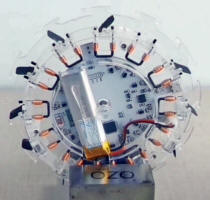

Ken Chan–Smart Chimes

Named Zhichime. Zhi (智) meaning smart or

wisdom in Chinese. Site visitor Ken Chan shares his innovative and

stylistic app controlled commercial chime set. Over 1½ years Ken

designed, perfected and built this Bluetooth connected musical

masterpiece.

The 12 aluminum chime tubes have an OD of 8mm. Six tubes have wall thickness of .8mm and the remainder are .5mm. Lengths ranges from 257mm to 427 mm, producing selected notes from C4 to F5.

Chimes are supported with fish line to the controller disk using magnetic flip disc as the striker in a transparent container.

You can create a melody to your liking. There are pre-programmed tunes such as Happy Birthday, Jingle Bells and Twinkle Twinkle Little Star.

You can learn more from Ken's website and YouTube.

Rickey Absher made this Corinthian bells B scale chime set from 2-inch aluminum and used #18 black nylon cord for support. Purchased from Amazon, he used a small tube as the axle for the striker. There was sufficient tubing to make four axels.

Installed in my sculpture garden in the beautiful karri forest near Augusta

Western Australia, Hylton Quail names this "Ode to Joy." The tubing is

galvanized 32NB pipe with a 3.2mm wall and supported with stainless multi-strand

plastic coated shark fishing wire and crimped.

Chris made this 5-chime set to hang in front of his business, The Gold Bar, on Koh Tao, in the Gulf of Thailand. Constructed from 2-inch aluminum pipe with a 3 mm wall, the longest tube is 1½ m for C3 and ends with D4.

Parker from Nashville, TN used teak wood for the support disk and striker. The wind sail (in the shape of Texas for his wife) is mahogany. The tubes are galvanized steel and (loosely) tuned to the Corinthian Bells Key of G, starting at the C5 octave. The wire rope support line gives is a uniquely artistic look. They sound way better than he expected.

Russell Sparks made this unique and highly polished chime set for his mother using his wood and metal working skills. The first letter of his mothers name was used to craft the wind sail. In addition he used a knife-edge on the striker. Russell has some useful finishing tips here in his video in a holiday setting.

Jenna used 1-inch copper pipe tuned to the B scale to craft this chime set with a beautiful hand painted wind sail in a peaceful country setting.

Stephen from Cornish, NH rebuilt a 25 year old dilapidated set of Woodstock chimes using teak for the top support, black locust for the striker and mahogany for the sail. 65 pound test coated stainless steel fishing leader wire supported the chimes and a stainless steel fishing swivels to connect the striker to the top support and the sail.

Jonathan from Florida enlisted help from his father (both engineers) to make this 2-inch copper set for his wife. Pleased with the results him mom and aunt now want a set. Sounds like this project will continue for some time, no pun intended.

Rotating Chime Set by Orion: plays an 8-Note Melody

just as he envisioned it would. Watch the video

HERE

14 Orchestra Pipes Chime Set by Debbie from

Illinois displayed on an antique engine gantry.

Debbie

and her husband used turnbuckles as described on the website to hang the top

support plate and to hold the striker. After two weeks in the wind the

turnbuckles unscrewed causing the set to fall. So we recommend using some

Loctite® on the threads and in some

instances a double nut.

Large

Chime Set in Metal Mesh Artwork by Cladio from Italy made from 100 mm aluminum.

Beer Bottle Striker and Hand Embroidered Wind Sail

by: Doug

Copper

Chime set by Joe

Joe

is a retired plumber and his first effort at making chimes. These are 1 inch

type L copper mounted on a old 6 spoke valve handle 12 inch diameter. My striker

is a smaller 3 inch brass valve handle. The sail was made from 2 inch copper

pipe that I split and opened up flat.

See his video HERE

For many years Doug Groves has used this website to make wind chimes for family and friends. Shown here is a special set for his sister. See his video here.

90 MPH wind speed peaking at 140 MPH, June 2020.

So, how do you build wind chimes to survive winds meeting the definition for a category (1) hurricane, peaking at a category (4)?

Kelly form northern Nova Scotia has done just that. Her solution was 2-fold - place the chime set on the opposite side where the high winds arrive. However, on that side we still get 90 MPH + winds several times a year.

Use very heavy pipe. I found an old rusty 2 inch pipe with 1/8 inch walls and cut a C4 set for Westminster tuning. Unfortunately, it wasn't long enough for a C3, which I wanted. The only problem is the weight. They are so heavy that it's tough to get much volume out of it, but it resonates until tomorrow. Note the fixed support using the building timber.

Kelly explains the winds are an amazing natural phenomenon, caused by the 3-body intersection of warm air from the Gulf Stream, stable air from the West, and the highland plateau. With a build-up of pressure, the warm air forces its way through to the West in a venturi effect. It picks up speed downhill before it hits our community and the surrounding area. To survive: build strong. Our house is 150 years old, built with mortise and tendons. Keep the yard clear (or the wind will do it for you).

Dan Sodam designs another beautiful set of 2 inch aluminum shower rod chimes for his backyard. This 8-chime Saint Michaels set incorporates solar lights for night time viewing. Note the heat shrink tubing used for knot tails. May 2020

.

Matthew Lauletta used 1" steel conduit starting at C4 (32 7/8") and moving up to A. They are internally mounted with para-cord attached to 1/8" steel rod. He has enough pipe cut to make 3 more like this and makes small improvements on each as he builds more. Then plans for 2 inch EMT are in the future.

Non-Traditional Materials (A Great Father/Son project).

I am building sets of Christmas gifts for my family this year. I had started by using wood pieces for the base and striker and finding decorative metal pieces at local craft stores for the sails. My son took a recent interest in making resin coasters and paperweights as Christmas gifts and we thought we could make the wind chime parts out of resin. We found some small cake molds for the bases, small circular and hexagon molds for the strikers, and larger circular and heart shape molds for the sails.

I've been experimenting with different metals for the tubes (copper, aluminum, steel) and different methods of hanging (standard two-hole, 1/2 wrap, and copper V-pin). My son has been experimenting with different colors and thicknesses for the parts.

Brass Chimes by Debbie B. from Illinois salvaged this commercial set of 14-brass chimes that had been improperly mounted and without support plate or striker. She corrected the mounting location to be the 22.4% location and crafted a new mounting and striker.

Copper chime sets by Carl Kinder.

The tubes are 1-1/4" type-M copper, that have been brushed with a

sanding disk from different angles, heat treated with a torch, and then clear

coated. Tubes are tuned B, C, D, E, F, and G The set with the blue ball & beads

used an experimental low temp plastic resin powder coated clear coat. The wind

sails are made from plasma cut copper sheet that's also been heat treated and

clear coated. The knocker is made from a hobby builder's clock face with

decorative curtain hanger rod ends. All tubes are suspended by 50# test fishing

line that's been strung with decorative beads.

Clearance sale inspires wind chimes!

Edmund Haremski, from Buffalo NY was in Lowe's Home Improvement store one day when1-1/4” and 1-1/2” copper pipe was on clearance for 75% off. Purchasing an adequate supply and applying his woodworking skills, Ed use the information on this website to fabricate his chime-set. The bell shaped top support and decorative striker was made using his wood lathe. The striker is wood, but the point at which it strikes is made from Corian. The original wind catcher was too heavy, so he replaced it with this stamped metal flower he found at Walmart for about $5. Ed used the half-wrap method to support the chime tube. He already has request from family members for additional sets.

Aluminum Chimes by Bill Carpenter.

I’ve been using aluminum tubing, mill finish, anodized, and bright anodized. All work well. I purchased them through Amazon, a local supplier, and ACE Hardware.

Supports I’ve made from hardwood, mahogany and black walnut. I used scrap pieces from my woodworking hobby. The striker has chamfered edges to present a narrow striking surface.

I've used a braided micro cord, 1.18mm from Atwood Rope Mfg and purchased through Amazon.

On the first wind chime I made, I used copper wire to make inverted “v”s with a single cord for hanging. On the subsequent ones, I used the traditional double cord pass through hanging method.

I’ve experimented with wind catchers, including a wooden orthogonal sail, and found a large 8” Reuleaux polygon to be very effective. I also made a real sail from sailcloth and a dowel frame which I’m still testing. I find that having a wind catcher heavy enough to set up a resonance with the striker as you suggest to be very effective.

At first I thought the “real” sail was a good idea. Then after I finished it, I got a little disillusioned. Now I’m back to thinking it’s a good idea. So I may try a more ambitious one with a small boat hull for a little more weight, and maybe a mainsail and a jib. The hard work is cutting out and sewing the sail, and then the rigging. But I’ve got a little experience now and it should go better with the next one.

I also got a scrap piece of sheet aluminum, 1/16” thick, from which I made a 5 1/2” square wind-catcher. It works very well and it has the right amount of weight for resonance.

Some items from my experience I’d like to pass on:

• I cut the tubing on my table saw using a cut off sled and a 7" aluminum

cutting blade.

• To cut burrs off the inside of holes drilled in 1” aluminum tubes, I use a 6”

half round crosscut file.

• To cut out the wood circles for supports and strikers, I use a home made band

saw jig I got from the internet. Then I use a similar jig to sand the pieces on

a disk sander.

• I make my drilling patterns by drawing a full size layout on 1/4” grid

sketching paper, and then copying it to a stiff paper cover stock.

• To determine the length of cord needed for hanging (I use holes drilled

through the support), I use a spreadsheet to add up the hang lengths, thru the

tube lengths, thru the support lengths, space between the chimes and support

distances, and the distances across the top of the support to get an overall

length. Then I add a few inches for good measure.

• After cutting the cord to length, I use Duco Cement on the ends to create a

stiff, un-frayed end which is easy to push through holes. I can get it through a

1/8” hole through 1” tubing on the first try most of the time.

• Once I get the chimes at the right height, I push a small brass nail through

the hole beside the cord to lock it in place. Cord ends are secured with knots,

either just a common overhand knot, or a figure 8 knot.

In addition to making the 4 chimes, I’ve repaired and renovated 4 sets, one of which needed three aluminum rod chimes that had been lost. I’ve also renovated an old “chimealong” with 12 chrome plated 7/8” steel chimes, 3 of which were missing. I quickly found getting a small quantity of the right steel tube chrome plated was a lost cause, so I found some stainless steel which I used. I calculated the lengths from the excel tables on the website, and they turned out pretty good. A picture is attached. The new chimes don’t have the blue hang point marking tapes on them.

High School Music Class in New Jersey makes wind chimes.

Each student

made the striker, sail and support

plate by hand and cut/tuned/mounted the chimes on their own!

The teacher provides students with a basic outline or structure for the

project and the students took it from there, which is why each project came

out unique.

Aluminum Chime Set by Lisa at Gourdous Creations.

See her video Here and the second video Here

The set features a copper roof and a copper wind sail.

Dual

chime set. One chime set inside another made from aluminum tubing by Gary

Kester.

Made for a very special mother-in-law.

One set is 16mm OD x 14mm ID tuned to C4 for the longer chime. The other set is 10mm OD x 8mm ID tuned to C5. The top support structure was 3D modeled and printed in PLA+ plastic. Each set has its own striker. A bronze coat was added to provide a metallic finish. I sanded away the metallic finish from the translucent plastic by the icons to make it look like a cutout and let the sunlight pass through. I used the hang points as a guide to determine the size and layout. See the video HERE

Steel Tank Chime by Michael Smith.

The orthogonal sail was kept close to the ground because it can swing widely and could be a danger to people. The clapper is made from an industrial plastic material.

See video for the chime and it's orthogonal sail.

Aluminum 6 chime set, 2 inch OD by: Guilherme Rubesam.

Hear the chime set here: (Calm Morning) (Strong Winds) M4a format

Aluminum chime set by JP in Dubai.

BJ, using aluminum and copper, built her first set of chime sets for kids using a school bus, fire truck, 1910 Model A Ford and Uncle Sam for the 4th of July.

Aluminum electrical conduit by Dan Sodam.

2 inch aluminum conduit makes the silver colored pipe set using C4 Canterbury (6 pipes) while the 2 inch black aluminum set is C3 for the C9 chord (5 pipes). A bamboo cutting board was used to make the keeper for both sets.

Six square tubes chime set by Richard Maier from NH.

While our calculator is only valid for round tubing, Richard used the ratio calculator to select lengths for this chime set. The hang point remains at the 22.4% location and allows the tubing to resonate to its maximum ability.

The top cap was from a hole cut into a walnut cutting board for our dogs food dish. The top edge was rounded with a 3/4" router bit. The clapper/hammer is a piece of left over pressure treated decking cut into a hexagon and rounded over on top and bottom with the 3/4" router bit, and stained with walnut stain. The sail is a piece of pine sanded with a flute on one side and stained with the walnut stain again. All of the wood has about 5 coats of Helmsman Spar Urethane. My daughter did the writing and the art work.

I tried jewelers chain first but it was not strong enough to carry the weight of the tubes and switched to a slightly heavier chain from Lowes. With an old umbrella I cut the pins for the tubing hangars and was able to pull the pins up with a screwdriver to bend then so they would center the chain in the tubing. I didn't find a good way to finish them off on the outside of the tubing so they were just bent over and cut off, then filed a little.

Additional photos here: Photo 1 Photo 2 Photo 3 Photo 4 Photo 5

Eight tube copper chime set by Don Homan.

I built two sets of chimes utilizing "L" type copper tubing, the larger having eight 1" OD pipes tuned to the St. Michael's chimes (two octaves lower), with the smaller utilizing 3/4" OD tubing and tuned to a d-minor pentatonic scale. The base and striker on the larger set were made with 5/4 purple heart hardwood (Brazilian), and the smaller set were made with African sapele hardwood. Both strikers are star-shaped, and the bases are simple octagon/pentagon shapes. Both sets utilize your orthogonal sail, but I used sheet copper for the sail in being consistent with the copper theme. Additionally, the pipes are center hung as I drilled and inserted 1/8" copper pins and soldered (sweated) the joints. Removal of the excess was a snap with a fine file and sandpaper, and the joints are nearly impossible to find. See short video here

Two Tube aluminum chime set by Mak Kern. I made these Dream Catcher Meditation Chimes using your chart-

for aluminum and painted the chimes to look Brass [ the rings are actual

Brass.] The "sail" is marble stone and acts as a weight that everything spins

around, so by spinning the ring you activate the chime. The fishing line that

hangs everything, coils in one direction and then unwinds so that even a little

spin activates the chime for awhile.

Five Tube Copper Chime Set by Gareth Thomas, England.

From a discarded section of type M copper tubing Gareth fashioned the set from mostly recycled material. Selecting notes E flat, G, B flat, D and F the chimes are bottom aligned and supported with a thin cord from an end cap. Take note that Gareth first used thin braided S/S wire (1.5mm) to support the chime from the end cap and it had a lethal effect on sustain time.

A polished abalone shell makes the perfect wind sail. Listeners enjoy a sustain time of 30-45 seconds. Hear their soundRead the construction details

HERE.

Five sets of 2017 Christmas gifts made from 3/4" copper pipe, cedar supports and strikers with hammered copper sails, 40 lb mono support line below support plate, 80 lb Dacron above, by Jonathan Fenton.

Sculptured copper chime support by Nick Leith.

Recycled 3 1/2 inch schedule 40 steel tubing featuring the natural weathered finish by Dan Coyne, Lodi, CA.

Tuned to the major pentatonic scale, the sculptured chime set weights in at 210 pounds with the longest tube (E4) about 50 inches. The 9 inch striker is made from a recycled red colored nylon cutting board while the chime set is displayed showing the lush native California backdrop.

You can listen

HERE .8 Meg mp3 (note the exceptional sustain time)

Largest

tuned bell chimes in Europe.

exhibited at Mozirski Gaj Botanical Park in Mozirje,

Sloveniain

By:

Length 19 feet 4 inches, 7 inch, (180 mm) OD aluminum,

wall thickness 5 mm, tuned to: C - G - D - E - A.

Chimes by Paul and Alice Johnson

What to do with a random collection of Type L copper water pipes ranging in diameter from 5/8", 7/8", 1 1/8" and 1 5/8", was a question B

ob asked. A coordinated collection of five notes, C1, D1, B2, E4 and C3 makes this very attractive chime set stand out in a scenic mountains background.

Stainless steel tubes with a 38mm diameter and a wall

thickness of 1.2mm.

By Riho from Estonia.

Watch the video here 5 Meg, WMV

Most of the internal support pins are welded in place and ground to a smooth surface. Originally, Riho began with a wood clapper but later switched to a soft plastic for better longevity. No difference in sound was noticed when switching from wood to plastic. Alignment began with a bottom arrangement but switched to top aligned because the high winds caused the chimes to bang into each other.

6 x 110 inch aluminum with a 1/4 inch wall makes this C3 chime for the Miami Meditation Center.

Used to create focus, Bill Durahm designed the

chime specifically for this meditation center. The large diameter was selected to provide a sufficient surface to adequately radiate the fundamental C3 note of 65.4 Hz, and to allow for a large range of overtones.

10 Chime Magnesium: In the plumbing business, Wes discovered that magnesium water heater anode rods produce a nice sound. Aluminum is very close to magnesium so tuning was done using the aluminum selection in the calculator. The diameter is typically .9 or .75 inch. Wes used a keeper-striker to allow the ten 10 chimes to maintain position and prevent tangling.

Aluminum in a variety of sizes by: Richard Jupp, near Melbourne, Victoria, Australia.

Hand-crafted to order in the Dandenong Ranges, Richard has developed a community-based business,

Mountain Song Wind Chimes, with a little help from this website. Manufacturing wind chimes is not simply to 'turn a buck,' but because he has a one-eyed passion for them. He thoroughly enjoys the delight expressed by folks as they listen to their gentle resonant tones! With a strong musical interest and a background in physics, professional careers in engineering and sales, and solid workshop skills, Richard encourages a custom design specific to the customer. In addition there are a number of 'off-the-peg' designs.

Uniquely supported copper and aluminum chimes by Thomas Warman, North Texas His wife's favorite, the Double Chime, is 1 inch copper about four feet long flowing across two octaves, while Tom's favorite sounds fantastic, it was inspired by eastern culture and is 1 inch aluminum about 16 inches long. The Moon Chime is also 1 inch aluminum about four feet long and remains as Tom's second most favorite. In a effort to gain a better understand about the science of chiming the first few chime sets were standard designs from copper, EMT-steel and aluminum tubes sized from 1/2" to 1" in diameter. Considerable effort was placed on achieving the desired sound with help from his wife's piano skills. A family favorite weighting 40 pounds and hanging in the front yard, 'Mac Daddy' is made from 1 1/2" EMT about 5' long. Tom also made good use of the orthogonal wind sail.

3 inch Steel tubing by Art Gustafson: Designed specifically for the

Oklahoma Railway Museum, the colors green and yellow are in keeping with the museum. On occasion, chimes can become quite annoying when the wind is gusting strong. Art has designed a unique method for quieting chimes in just those situations. The rotating wood disk rest on top of the aluminum keeper-striker and can rotate to three predetermined positions, full volume, half volume and 90% quiet. Thank you Art for adding yet another useful design element to the art of chiming. Art plans on making a similar set for the Oklahoma Animal Shelter. See Art's video HEREAn inspiring journey by Shirley Kennedy See her website here.

I wanted to thank you for the information you have provided on your website

for making Wind Chimes. When my husband Bill and I were stationed and lived in

Beaufort, SC (1992-2000), we would travel to Florida to see my mother and

father. In one of our many adventures together at a flea market, I had bought a

set of homemade large chimes from a very nice lady. Her and her family had a

home base operation. My family and I also made a visit to her house and watched

her make the additional set we bought for my mother on that day. In her yard she

had chickens that laid green eggs. How cool is that!!! That was the beginning of

my dream of what I wanted to do with my next life….and maybe I could even sell

them as well.

So fast forward to now.

A year ago I was sitting in a cubicle and not very happy with the journey…So after many discussion with my husband, I decided to resign and start a new chapter…maybe I could make chimes with the help of my husband (of course after all he will have to operate the equipment.) After much research on line I found your website to be the most helpful and useful. I am at the developing and growing stage. We have created a workshop in our basement next to the washing machine and dryer (and my husband is still operating the equipment…the chop saw intimidates me…I will get the courage.) I am currently creating a website, it will take me awhile. Also, I am operating in the red for now. That will change. Our business is named

Chimes by B & S and we can be contacted at this email. “This is a journey not a destination.”5 - Octave Chime Mobile by Tom Zarzaca, Georgia, USA Video here 72 Meg, MP4.

An amazing five octave chime mobile from five, pentatonic scale chimes sets, six chimes each. See the video and observe the free casual motion of the mobile. The tubing is aluminum with 1/8” walls, but the arch has a 1/4" wall. The chime set diameters are 7/8”, 1”, 1-1/4”, 1-1/2”, and 2”…with the shortest tube about 9” and the longest 84.”

3/4 inch EMT by Vic from Vancouver – Listen Here, 2 Meg, MP3 (Note the beautiful bell like sound).

Made as a present for a friend living on the seashore, I painted the pipes silver, the striker green and the top plate color is blue. The wind catcher I acquired from a dollar store and serves the purpose. I reduced the size of the striker diameter by half inch but increased the height. This was done by inserting a dowel inside the bottom of a tin can bottom. Reducing the diameter but increasing the height keeps the striker weight the same. The chime sound is slightly clearer in pitch, but sill good. I also provided a wooden striker with the chimes as an option, which can be replaced any time. The wooden striker gives a slightly muffled sound.

Steel chime set, 2 mm wall thickness steel by: Michael Beazley, UK.

A chime set for our sensory garden at our local primary school came out perfectly first time with the help of your designs and pre-calculated tables. The latter saved me hours of trial and error, and was inexpensive to make. The tubes were tuned to a chord of F sharp minor 7th - a nice dreamy sound for a sensory garden I think. They are located in a windy spot fairly close to local homes, so the striker is a light wooden disc wrapped in faux leather for a soft tone.

With six of the older children, we talked about the way tubes create sound, identified the notes on a keyboard, and they checked the 22.4% measurements: then assembled the chimes from the "kit" of cut, drilled and painted tubes that I made. They then explained this back to the rest of the class, and we all went outside to hang the chimes from a tree. All good ways to apply their math and science!

EMT by Valerie: 1 1/2" EMT (Steel) cut for the pentatonic scale at C4.

Pictured is the American themed chimes that I made based on your information (just in time for the 4th of July). The longest chime is just over 40 inches tall, and with the wind sail and top support; it is around 5 foot tall. I stenciled the stars on the top support in white paint, and used a special paint for the tubes as they are galvanized, and most paints will not adhere well to galvanized metal in the long term. I love the star strikers (and it matched my theme), so I made it with the star instead of a regular circle striker. I used a turnbuckle on the striker as it makes adjustments very easy, and it provides some weight to the striker. The turnbuckles work beautifully. I also made one of your special wind sails, but instead of aluminum, I used thin plexi glass, and cut it with a jigsaw. I works amazing!!!! I have made five sets of chimes now, and I replaced all of the original windsails with your specially designed ones because they work so much better.

The Chimer by Bill Stoyer: Bill has repurposed this old Emerson

piano into his Chimer.

Copper tubing chimes covers two octaves (+), 26 notes. Note the particularly

excellent work that allows the tube to be stabilized after its struck, yet

maintains the sustain note until key release, and the effective back lighting.

Watch his one minute video here:

www.youtu.be/o5uzKmpakuU.

Al Brendel has created a Arduino controlled set of windless chimes suspended horizontally from the two node points. From 5/16 inch aluminum tubing, the 16 note player was tuned in the Key of C with the lowest chime at a frequency of 2,637 Hz, which is E7. See his well done DIY description with videos on Instructables.

Note: Arduino is an open-source electronics platform based on easy-to-use hardware and software and intended for anyone making interactive projects.

This Bespoke Wind Chime Sculpture was designed and created by David Harber Ltd, and consulted on by Leland Hite, wind chime specialist. The sculpture is situated in a garden designed and created by Ryan Donohoe of Donohoe Design. Photo by Ryan Donohoe.

Eight 3½ inch mirror polished 3/16 Stainless steel chimes feature the concealed striker mounting system. In general. the concealed striker is not an effective method for striking a chime with enough energy to be heard at a distance. So in this application, considerable work with extensive experimentation, finally resulted in a robust strike that produces a charming sound throughout the garden.

Mike Mellelieu, Tauranga, NewZealand, has sculptured an unusual feature into his pond design using a water driven striker for the chime set. A copper fountain sculpture, with falling water, activates rotating copper tubes to create a chiming effect similar to wind chimes. The sculpture stands about 1.8 meters tall, and has taken a month to design and build, being a long process of trial and (mostly) error. Measurements and counter weights turned out to be critical. As far as I am aware this is a unique concept for chimes in a garden pond.

Watch the daytime video

HERE and the nighttime video HERE.

3/4 inch EMT (bottom aligned) by Mark using 1/8 inch Lexan sail

(36 sq. in) and a wood striker.

A3,C4,D4,E4,G4,A4

I couldn't help but wonder what an octave up or down would sound like so I made two other sets. I made one an octave higher - 5 tube with A4,C5,D5,E5,G5 and it is a very nice sounding chime. I have this one alone in a little tree in the front yard. It is a beautiful sounding set. I may try a little harder striker. Right now it is just a 3/4" thick pine disc.

Then I made a bigger set for an octave lower - 6 tube again.

A2,C3,D3,E3,G3,A3

The small set has a very neat airy bell sound - not very loud but nice in the

front yard. The middle set has a full deeper tone. I used a harder wood for the

striker and I think it is a little harsh, but my wife likes the sounds.

Both of the larger sets are under a back yard pergola. Even though they are cut to the same notes, and play well together, each set sounds so different from the other!

It does not have the smoothness and sustain of an older set of purchased aluminum tube chimes that we have. (1 ½ " tubes with 1/8" walls) I think the longest tube on the aluminum set is about 20 something inches.

The lower octave set has a nice deep tone. Not quite the sustain again of the

thick aluminum tubes. It definitely has the sound of church bells.

(I like the sound of a baseball striker, but it would take a lot of energy to

get a good sound - I have a pine disc striker again on the larger set.)

To clean up the inside of the drilled holes on the last set of tubes, I carefully used a small piece of wire coat hanger wire with a small sharp bend in it and my electric drill. I got the little bent end of wire inside the tube, making sure it would make proper contact, and spun it while pulling out on the drill. In doing so, it made this hard wire piece smooth the inner lip of the holes. I know it worked better that the previous attempts at sanding on the others because the string fed thru much better and smoother.

1 inch 304 SS x .049” wall by Tom Mitchell, New Jersey.

Other chimes sets by Tom included custom wind sails, cut using a jewelers saw, from .09” thick aluminum.

Nine

tube copper chime set by Gareth Thomas from England.

Nine

tube copper chime set by Gareth Thomas from England.

Read the complete write-up describing construction:

here 700K, PDFListen to the sound: Here

3.3 Meg, MP3I used 9 tubes, 3 of each size, 15mm, 22mm, & 28mm, longest of which is 27in and shortest 10.5in, so a huge spectrum of possible tones. They are all ‘old copper’, which means they are thick-walled, but not necessarily perfectly uniform, made 50 or more years ago. Overall hanging length from top of stainless loop to bottom of sail: 42in. Striker 3 1/4in, with a striking gap of 1/4in gives striking diameter of 3 3/4in. Tubes of three different diameters are set on three separate radii: the narrower ones closer to centre, with outer tubes just inside support disk. The inside contact point of each tube is exactly on the striking diameter, & tubes are arranged on this so that the contact points are equidistant from each other on that circle. This gives all an equal chance of being struck.

Building

Big

5-Chime

Set, 6" diameter x 13 feet long, aluminum, C9 Chord by Chris from Wisconsin.

Building

Big

5-Chime

Set, 6" diameter x 13 feet long, aluminum, C9 Chord by Chris from Wisconsin.

Pictured with the chime set is Chris's son, 5 ½ feet tall, and helps to demonstrate the overall size.

My chime supplies are from a local metal recycler making them very affordable. They get some of the craziest stuff and not just aluminum cans either. The support disk is a 1/4 inch aluminum plate cut to form a 24 inch circle.

I

made a jig using a 2 x 2 piece of pine and a couple of nails to work as a

larger than life compass (pictured right) for scratching a circle in the

plate. A jig saw with a metal cutting blade worked well to cut the circle.

On the top support plate I drilled four evenly spaced holes, 90 degrees from

center, around the edge of the disk to support the top plate using chain

attached to the support rope. Five evenly spaced holes near the

circumference were used to support the tubes. After I made this chime set, I

did see some precut wooden disk at my local hardware store, that would have

worked well.

I

made a jig using a 2 x 2 piece of pine and a couple of nails to work as a

larger than life compass (pictured right) for scratching a circle in the

plate. A jig saw with a metal cutting blade worked well to cut the circle.

On the top support plate I drilled four evenly spaced holes, 90 degrees from

center, around the edge of the disk to support the top plate using chain

attached to the support rope. Five evenly spaced holes near the

circumference were used to support the tubes. After I made this chime set, I

did see some precut wooden disk at my local hardware store, that would have

worked well.

The

support line for a chime is .032 braided stainless steel cable. It runs

about 27 cents a foot at Home Depot. To solve the problem of supporting the

chime on its center, I used the same stainless cable to form an upside down

Y connected at the 22.4% location. Two 8” cables were used in each chime

with which loops were created at each end. Ferrules (pictured right) were

used to keep the loop in the cable. One end was fastened to the inside of

the chime with a stainless 1/4” bolt and the other was attached to the cable

from the other side of the chime, and held together by the cable used to

hang the chime from the support disk. I am trying to hang all my larger

chimes with one line in the center of the chime. By doing it this way, it is

always in the center of the chime and not sliding to one side or the other.

The

support line for a chime is .032 braided stainless steel cable. It runs

about 27 cents a foot at Home Depot. To solve the problem of supporting the

chime on its center, I used the same stainless cable to form an upside down

Y connected at the 22.4% location. Two 8” cables were used in each chime

with which loops were created at each end. Ferrules (pictured right) were

used to keep the loop in the cable. One end was fastened to the inside of

the chime with a stainless 1/4” bolt and the other was attached to the cable

from the other side of the chime, and held together by the cable used to

hang the chime from the support disk. I am trying to hang all my larger

chimes with one line in the center of the chime. By doing it this way, it is

always in the center of the chime and not sliding to one side or the other.

Using a stout tree branch, 15 feet from the ground, I threaded rope thru a pulley to hoist and support the chime set.

A couple weeks after completing this project I learned about the possibility of corrosion between the SS bolt and the aluminum tubing, caused by the dissimilar metals issue. Next time, a plastic washer where the two metals meet would solve that problem.

Chimecco 600-pipe wind chime: This truss supported 600-pipe wind chime is made from 2 inch (50mm) diameter aluminum with lengths from 4 ¾ inch (120mm) to 12+ feet (3750mm). Notes cover the entire span of the music scale, and while not all fundamental notes are audible, there are an ample amount of overtones to produce a bell-like sound.

1” diameter X 0.065” wall AL 6061-T6511 by Paul Stoops.

I just finished building a 5-chime set according to information at https://leehite.org/Chimes.htm and they produce fabulous bell like notes on the C3 scale. I used the Syntrillium software to select the desired pentatonic scale -- Major Pentatonic (Asia).

Learn about Paul's build information and construction details, including an excellent approach for fastening the chime to the support line.

Bill Moyer used eight, one-inch copper pipes with a

pentatonic scale tuning beginning at A3, for this artistic arrangement including

small copper bells from a two tier support ring. On top is a solar light fitted

to the bottom ring of the frame work.

Bill Moyer used eight, one-inch copper pipes with a

pentatonic scale tuning beginning at A3, for this artistic arrangement including

small copper bells from a two tier support ring. On top is a solar light fitted

to the bottom ring of the frame work.

Bryon Bren discovers schedule 40 aluminum pipes. "I had been sitting on the idea of making some big chimes for a few years. I initially bought some scrap gas cylinders to make some bells. They kind of worked but tuning them turned out to be problematic. Anyways, I had a bunch of schedule 40 pipe lying around and decided to give it a shot. I had no idea pipe could sound so great."

See them in his YouTube Video.

Mr. Tomáš Jarošek from the Czech Republic has tuned a single chime tube for three separate frequencies, the fundamental, the first overtone and the air column resonance, often using his tuning of symbolism. Quite an amazing task.

I do the tunings from my point of view, cognition, experience and feelings to resonate with its symbolic meaning...

NEW YouTube video demonstrating the three tunings www.youtu.be/f0iisKnatsY?list=PLUuCD-Ex8adR_Iudy9L2H8YaAwzwy_3gH

Additional videos are in his native language and with English subtitles. www.youtube.com/user/tomashjaroshek?sub_confirmation=1

From Mr. Jarošek:

"I was studying a music therapy and I started to be interested in tuning, music theory, music physics and math. I needed "something" to test theories which I was working with. Chimes looked like a good start. One day I was going by junkyard and I saw an old rusty lamp. That one which has a light on long tubes. I said that's it! I was able to test Pythagorean tuning which I was just discovering, and this was the result:

https://www.youtube.com/watch?v=ydGR0JHREUA&list=UUxNTFD-_7ki93BKIjaAbgiw Yeah, you can see some mistakes at first sight, but never mind, this is my first! :)) Some weeks, maybe months passed and I took this chime to one meeting in nature. A lady saw it and asked if is it possible to order something like that. I said well it is possible :) And this is how started mine custom handmade chimes...In these process I research a lot in making and tuning chimes but (not just) in the start your website helped me a lot! So thank you for publicizing them ! Since then I started to making self resonating chimes with tuned inside air column, I love these one :) and the last "masterpiece" is chime with 3 tunings in one tube! Classical tuning of primary tone of metal, inside air column tuned to this primary frequency but also THIRD tuning! and that is tuned first overtone! wow that was something to do it... my head went crazy about that... you tune one frequency and distune the other two... oooh... But the result is quite awesome for me.

2" type "L" copper pipe made into copper bells for Christmas presents, by Jon.

Here are some 2014 Christmas presents I made for our best friends and grandchildren. I started out with 2" type "L" copper pipe and made a pattern for making a one piece bell, and then folding it all after tempering it to get it soft. Then I hand hammered it to get a nice ring and get an old fashion type look to it. Made some copper rivets to hold the sides together and then soldered sides. The strikers are made from pipe ferrules filled with solder. The ones shown are about 3-1/2" tall by 2-1/2" sides at their widest point. The one with the bigger striker has a better sound (IMO).

2 inch OD Aluminum with 1/4" wall thickness, tuned to the C-9 Chord beginning at C4. By Ken.

See Ken's video, note the great sustain time from the 1/4" walls. Video, 1 Meg, MOV

Here is what I got from eBay ,https://www.ebay.com/itm/200663170767?_trksid=p2060778.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

I got 5. My mom wants a wind chime that my late father was

going to make for her but he got to sick then passed. So I will make one for

her. I want it to sound wonderful for her. I paid for that app so I can tune it

like you showed on your site, Instuner.

THANKS so much for your help...

Ken….

8 inch x 20 inch Tank Chime by Bruce Naimy.

A wonderful setting for a tank chime made from a CO2 compressed gas cylinder with the bottom cut off. The tank measures 8” ID and 20” tall with a ¼” wall thickness. The striker is from a 4 ¾ inch steel disc, 1/16 inch thick and uses a 12 inch axle for stability.

2" Aluminum, Traversed Mercator by Caleb Marhoover.

A sculptural/musical interpretation of the distance which divides my youth from adulthood. Here, this journey is presented through the linear elevation profile of the terrain which fills that divide.

Tides by Margaret Noble.

Tides was to be a series of dynamic public art concerts with large-scale sculptural kites, tuned wind chimes and performances by experimental choral singers. Formally dressed in black, choral performers were to improvise with varying bell note melodies driven by the kite lines they would fly. - See more Here

A lightweight support frame and a lightweight keeper/striker

designed to contain the chime tubes in chaotic winds accompanied the ultra

lightweight chime tubes (1 inch OD, .032” wall aluminum tubing), all of which

remained under two pounds.

A lightweight support frame and a lightweight keeper/striker

designed to contain the chime tubes in chaotic winds accompanied the ultra

lightweight chime tubes (1 inch OD, .032” wall aluminum tubing), all of which

remained under two pounds.

Merle Walther, 1.5" painted EMT, 3" wooden ball striker & Moose wind catcher.

Jon, 2" aluminum, July, 2013 (Set number 2, see set number 1 down the page).

This set is a little larger than the last ones. The tubes are 2" x .065 aluminum with the upper support a combination of 3", 2" & 1-1/2" copper pipe. Kind of a chandelier design for the support. Overall the whole thing measures about 5' tall. The striker is again Alaskan Birch with copper sheet used for the sail. The sail was made a little heavier than normal so it is not chiming constantly since it is located in a spot that picks up all our winds. The sound turned out quite beautiful thanks to your chart. The only thing that was not salvage was the chain used to hang the striker/sail assembly. The tubes were drilled and copper wire inserted for the hang points.

Tried something new on the top support. Applied Oatey soldering Flux and let it set for a few days in the rain to give it the patina. On the sail I used Miracle grow Africa

Juggling Joe Wagner Plays Chimes from Pittsburgh, PA.

Mike Hammond, 2 1/2" steel chimes.

I wanted to say thank you for all the information I got from

your website.

I used it to make my first wind chime and it came out fantastic.

Roger Deweese, 4" tank top bell, 5" high.

The paint is a metallic red with about 3 coats of clear over it. There is a 1/4" black striping tape put on prior to putting on the clear finish. The "clanger" is made out of 1/8" aluminum cut into a star pattern (it seemed to need a sharp sound to work well).

Jack Nash, 6 pipes of 2" aluminum rigid conduit, using the pentatonic scale.

Jon, 2 inch aluminum chimes.

The tubes are 2" aluminum. The top support structure is based around a 3" copper type L that was drilled out to accept 1/2" copper axle tubes that support 1-1/2" copper for each tube support. The striker is made out of 3/4" Alaskan birch (4" diam) and the sail is made from some scrap sheet copper I had laying around. The support lines are made from two strands of phone wire. Everything used was scrap/salvaged materials except for the small piece of chain used to hang the chimes.

Chaos Chimes by Roger

Sonntag,

Sonntag

Creations.

Formerly Newton’s Flying Magnets, now Sonntag Creations, Roger Sonntag uses

magnets with a chaos engine to create windless chimes in a variety of styles. In

addition, you can buy just the electronic controls and design your own version.

Contact: sonntagcreations@gmail.com Ph: 585-615-4236

Jay Do and Hung Do, Houston, TX, Type L 1 inch copper pipes.

I write to you today to send you our warmest gratitude, all the way from Houston, Texas. You have put forth so much effort, not just in your website and extensive research alone, but also by personally assisting those who require additional assistance. With your help, my father and I were able to craft a wind chime by hand, filled with sentimental value. Far more valuable than something you could buy at the store.

Attached to this email is a short video my father has captured, in order to show you what we have created with your assistance.

Firstly, we picked the material we were to use. We decided upon Type L 1” copper pipes. The smallest chime was 14 inches in length, and we added one and a half inches to every chime after that, for eight chimes, resulting in the longest chime being 26 inches. While this did not create any particular chord, it created an inharmonious, yet tranquil sound. Next, we moved on to the support disc. The support disc was crafted out of stainless steel, as to not rust over time. It has several layers, similar to a merry go round. Next was the striker. The striker was also made out of stainless steel, to withstand the test of time. Last but not least was the wind catcher. The wind catcher was also crafted out of stainless steel.

To make our wind chime more unique, we decided the wind catcher had to stand out. What better way to do that than to show what the chime creates? I printed out an image of an eighth note and a sixteenth note and glued one on either side. My father than used an engraver to scratch away at the note, onto the metal, resulting in a gorgeous, while at the same time unique finishing touch on the chime.

This project was a wonderful father/son project. Surely, if we wanted a wind chime we could have gone to the nearest gardening store and got one for so much less effort and money, but being able to experience firsthand, all the effort that goes into designing and crafting a unique wind chime by hand, well, that’s priceless. We are so fortunate to live in a time and age where people like yourself are able to share their wealth of knowledge with the rest of the world, and likewise, people like my father and myself are able to obtain that knowledge, and make use of it with a few clicks of a mouse. Thank you again for all your hard work. This wind chime will be a treasured keepsake of the family for many years to come.

|

Chimecloud by Lutz Reiter, Marco Dondana and Arnim Jepsen from the Chalmers Institute of Technology in Göteborg, Sweden.

Video Here We are three students from the Chalmers Institute of Technology in Göteborg, Sweden. We are all studying Interaction Design and this project was aiming to explore new interactive ideas and solutions to equip and constitute a culture house here in Göteborg. Read additional details here. The Chimecloud is an evocative, responsive sound and visual installation aiming to make users actively take part in the creation of soundscapes using their body and movements in interaction with the space surrounding them. It takes its idea from nature, where the wind is the main element creating natural soundscapes. The Chimecloud is using this as a metaphor, making the peoples presence and movement matter and bringing the space to live. 36 actuators (servo motors) triggers 216 chimes from user movements. |

|

|

Aluminum chimes by Duc Billy from Viet Nam. YouTube https://www.youtube.com/watch?v=iMhsM9cNP1I Facebook https://www.facebook.com/ChuongGioDofrance

|

|

|

Overall, I'm extremely happy with the chimes, they sure are a talking point with friends and family. There's also a footpath leading to a nature reserve that runs behind our garden: I've caught a few people taking photos of them..! The sense of achievement I got from making these chimes was worth the money alone, plus I've got a fantastic piece of functional garden art that should give me pleasure for years to come. I can't thank you enough for your help and guidance Lee |

|

|

Read the complete details here by Craig PDF

|

|

|

3/4" Copper Tubing Type M, by Michael Labbee. |

|

2.5 inch x .062 inch wall aluminum tubing by Neal

I recently built a wind chime for my mom as a Christmas present. She always wanted a very large, loud wind chime, but could never find one. I decided to take on the challenge of building her one from scratch, and I wanted to let you know that I could not have done it without your website. Thank you very much for posting the plethora of information.

I am a machinist, so I had easy access to materials and tools for this project. I used 2.5" round .062" wall aluminum tubing for the chimes. I had them polished at a plating shop. I made the support out of a piece of oak, as well as the striker. I turned the outside diameters of the support and striker on a lathe to make them perfectly round, and radiused the outside of the striker and stained both pieces. The support has a hole in the center for the mounting chain to go through, and I attached a hook so the striker and catcher could be removed easily if there was any unwanted chiming in the middle of the night.

The catcher is a piece of clear plastic. I engraved a quote on the catcher, it reads, "The pessimist complains about the wind; the optimist expects it to change; the realist adjusts the sails" I used wire through the drilled holes in the tubing to hang the tubes, and put hooks on the chains so the tubes can be taken down easily.

The chime sounds great, and resonates very well. Last Christmas Eve I hung the chime on my parents front porch, and put just the catcher in a bag to give to my mom. When she opened it, she was confused until I told her to go outside. Seeing the chime and knowing that I made it for her made her cry, happy crying of course. I just wanted to take the time to show my appreciation and share this with you. Thanks again! Neal

1 inch galvanized EMT by Jeff Zabriskie

Commissioned by my wife to make chimes for her mother, I selected the C4 size 1 inch galvanized EMT. Because I never wanted to have to redo ANY portion of the chimes due to weathering or wear, I used 3/16” Stainless Steel for the top-plate and dinger. The support cables are 3/16” Stainless for the primary and 1/16” galvanized for the chime supports. The internal attachment points utilize 12 gauge copper wire with the center bent up with the stick method. Once we get into spring, I might look into adding the mouse-ears to the top plate to get a little rotation if they need it, although we’ll see. The wind- sail is thin-gauge galvanized sheet metal modified to act like a CD, but I bent the edges to keep my support line from bending awkwardly and used rubber grommets so the sail wouldn’t simply spin. Jeff has a video for those that may wish to see it.

Aluminum & Copper wind chimes by Dan Shaw, Virginia

Swarovski crystals are used for the strikers while the hand carved Eagles are

from sinker cypress. The Eagles are finished using

Tung oil, white wood stain and mixed acrylic

paint.

![]()

1 1/4 inch Rustic Cast Iron water pipe chimes by

David Balfour

I made my striker and sail with small sections of the same wrought iron pipe

(1.68" galvanized water pipe) and welded on hooks. I am keeping the finish

natural (a bit rusty) but did coat it with WD40. The top leg support is made

from a triangle of half inch steel with stubs that the legs slip on to. The top

is an aluminum fry pan and it just sits on the to. I drilled holes into it to

hold the chimes and striker. I chose the metal striker because after I had one

strung up I really liked the clear tonal quality. I had some weed eater string

(.060") that I used for chime support. They kind of sound like church bells. I

didn't do any tuning except to measure the lengths. This was a fun project. I

made it for my wife since she wanted a set of chimes.

A Chromatic Chime Set, By: Dan Larson

Why? Just because I could. I have friends who ring bells in church, and I am

a closet piano player. When Pablo Casals played a Bach cello sonata VERY fast,

someone asked him: why so fast? He answered: Because I can. My son named my

creation C Machine, because it plays a C scale.

Read the entire account of this activity by Dan, very interesting.... Download Here PDF

1 inch Copper Tubing by: Musician, Travis Oberg, California

I chose 1 inch copper tubing and a chromatic scale C4 thru C5 (C4 was actually a test piece that I used and it's the only 3/4" pipe) and hung the pipes on a hardwood frame. Using the excel sheet as a guide I cut all pipe 1/16th long (as suggested) for fine tuning later. Using a hand file and a tuning device I tuned each pipe.

The most difficult task was hanging the pipe without causing buzz. I chose a solid brass rod which I cut to length, and bought a drill bit that was essentially 'one sheet of paper' smaller than the diameter of the rod. Hammering the pins (cut from the rod) into the hole allowed a super snug fit; the copper gave way to the brass, fitting very tight. No buzz! That was the most tedious part, getting the hole to be drilled fairly straight and hammering each pin thru. I also built a sustain pedal to allow the chimes to ring a desired length. This wooden pedal bar pictured at the bottom is spring loaded. All in all the project was a weeks work and I am super satisfied with the result. Sounds good! Thank you!

Chimes by Stanley,

Park City, Utah,

YouTube video here

Chimes by Stanley,

Park City, Utah,

YouTube video here

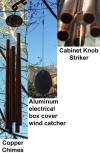

Copper chimes using a cabinet knob as the striker and an aluminum electrical box

cover for the wind sail.

A nice father/daughter project

Watch his video here wmv - 4 meg

Hip Chimes by John, Troy,

NY

Hip Chimes by John, Troy,

NY

Tubular not, but none the less, they are chimes. Yes, these really are

Chimes made from old orthopedic and dental implants that I have in my collection

from 32 years, e.g., hip stems, knee prostheses, acetabular cup prostheses,

dental blade-type implants, etc. Two of the hip stems are Ti (one is actually

just a scrap piece from machining a hip stem) and the other 2 stems are Co-Cr-Mo

alloy. When they are made out of Vitallium (a very hard Co-Cr-Mo alloy, usually

cast, but sometimes wrought), the ringing is terrific. (Ti-6Al-4V alloy

sometimes also rings pretty well.) (See the

(Hip Chime Video Here) WMV

The middle clapper thing is an old-style Co-Cr-Mo acetabular cup replacement,

which was meant to screw into the pelvis. The small rectangular plate above it

is a little Ti plate, which will hopefully catch the wind a bit.

Medical Chimes by John, Troy, NY

Made from orthopedic (and dental) implants. This one has 2 knee joint pieces in it -- the portions that would attach to the end of one's femur. One is made from Vitallium and the other from Ti-6Al-4V alloy. Also one of the other hanging things is an implant-shaped rasp (used to prepare the femoral site for a hip stem). The 4th item is a porous-coated acetabular cup (with a little inverted nylon bolt passively running thru it, as a hanger to let it ring decently. (There's a small dental implant threaded into the shaft of the nylon bolt so I can hang the whole thing.) The striker is a large chunk of left-over titanium alloy, which was left from machining another part. The 2 flat wind-catching plates are pure titanium and Ti-6Al-4V alloy, left over from some cell culture experiments.

Chimes by Chuck, from Columbus, Ohio, Nice use of chains.

I made six set of chimes based on the information on your site and gave them

away as Christmas presents. They sound great. Although, I'm not too sure about

using the chain to support the ringer and wind sail. It's probably too

heavy. See his

Chime Video

WMV

One bit of information you didn't explain is the need to create notes within the same chord in a given key. That way, any two or more notes that chime together will sound great together. My music teacher friend helped me select an F major 9th chord and a G major 9th chord.

1.5 inch EMT Chimes by David from Alaska

The set is contains 20 chimes from 1-1/2" EMT (electrical metallic tubing) with

a range from C4 to G above C5. The chimes are mounted in a frame of Jacobi wood

(sometimes called Brazilian Cherry). The frame construction is a combination of

mortise/tenon and screwed connections.

I also found a given type of pipe has a limited range of notes that will ring well. I put a copper wire through the tube and through the last link of the chain. Then I used a long stick that just fit inside the bottom of the pipe with a point cut on the end in the middle. I pressed the stick against the copper wire to put a bend in the middle so the chain will center itself. It is much prettier, more heavy duty, and more permanent than string. Finding the brass chain was the most difficult part. I used Trex decking to make the top support and ringer so they will never decay.

Commissioned Chime Set by Kenny Schneider

Commissioned Chime Set by Kenny Schneider

plays Bach's, Joy of Man's Desiring, when struck.

About me: I am a retired electronics engineer with a passion for

investigating technical issues, occasionally surrounded with mystery and

often bridging several fields of technology.

About me: I am a retired electronics engineer with a passion for

investigating technical issues, occasionally surrounded with mystery and

often bridging several fields of technology.

HOME | CHIME DESIGN | BIOMASS BRIQUETTING

Old Ham Radio Call Books - Cincinnati Triple Steam - Nuclear Aircraft - Emergency Medical

Leland Hite (Lee) K8CLI

All Rights Reserved