|

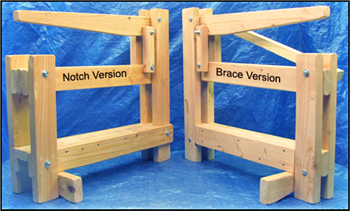

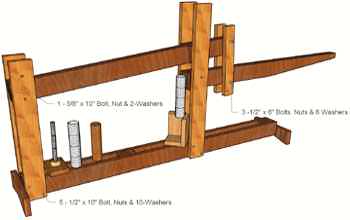

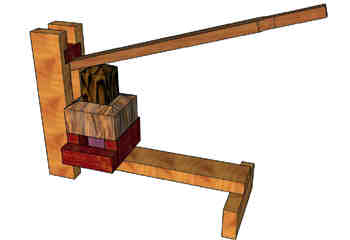

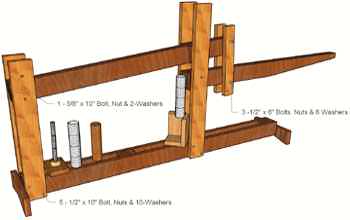

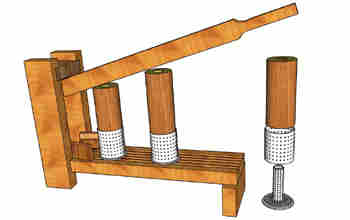

Micro Compound Lever Briquette Press

How

To Build A Micro Compound Lever Briquette Press Manual

North American lumber standard

1.5 inch

x 3.5 inch(38 mm x 89 mm)

{Includes English and Metric

Dimensions}, 2 MB, PDF

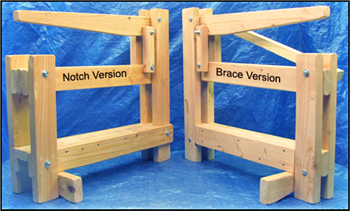

This small press works well for single-family use, classroom demonstrations,

or a small village.

It features a small footprint and

is easy to build using hand

tools. There are two versions, Brace version or Notch

version.

↓ Translated to the following languages ↓

Arabic,

Bengali,

Chinese (Simplified),

Chinese (Traditional),

Czech,

French,

German,

Hindi,

Japanese,

Korean,

Persian,

Polish,

Portuguese,

Spanish,

Swahili,

Urdu,

Vietnamese

Video

describing biomass briquette press.

Video about building the biomass press

by:

Ms. Firtle in Greece

How To Build A Micro Compound Lever Briquette

Press using 40mm x 100mm

Lumber (Brace version) Manual 1.3 MB, PDF,

Metric Only

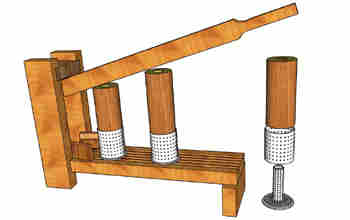

Biomass Molds

How

To Build Biomass Molds

Molds for shaping biomass into round, square, sticks, cubes

and chunks.

Drilled, slotted, and split PVC molds along

with slotted wood as an alternate to PVC.

Two caulking gun presses, split plunger pistons and more.

{English and Metric

Dimensions}, PDF, 6 MB

↓ Translated

to the following languages ↓

Arabic,

Bengali,

Chinese (Simplified),

Chinese (Traditional),

Czech,

French,

German,

Hindi,

Japanese,

Korean,

Persian,

Polish,

Portuguese,

Spanish,

Swahili,

Urdu,

Vietnamese

Briquetting requires a biomass

mold of one type or another, whether it is a small village,

single family, or classroom operation. Here you have choices

and there are no wrong or right, best or worst, good or bad

molds for making biomass briquettes.

A variety of molds will

work equally well and one type may be best suited for you

depending on the availability of construction materials, tools, cost, skill level, and briquetting requirements. This

document provides choices to consider when selecting a

biomass mold design.

See

Video for Split-Mold

testing.

Biomass Fuel Formulations

Biomass Fuel Briquette Formulations

(English)

↓Translated

to the following languages↓

Bengali,

Chinese

(Simplified),

Chinese (Traditional),

French,

Japanese,

Korean,

Persian,

Portuguese,

Russian,

Spanish,

Swahili,

Urdu,

Vietnamese

Courtesy Richard Stanley at the

Legacy Foundation

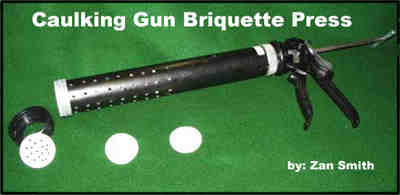

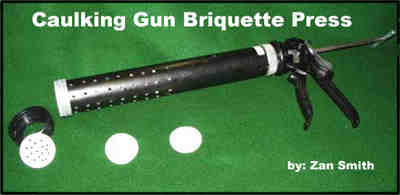

Caulking Gun Briquette Press

Caulking Gun Briquette

Experiment

by: Dr. Zan Smith

Good for classroom

demonstrations, formulation testing or small production

runs.

See

the updated version for this press in:

How

To Build Biomass Molds.

Caulking Gun Press by Joshua Guinto

(See

How To Build Biomass Molds for details)

Biomass Grinder

How

To Build A Dry Biomass Grinder/Thrasher Manual 2.5 MB PDF

Video describing the

Dry Biomass Grinder Thrasher Video describing the

Dry Biomass Grinder Thrasher

The grinder was designed to grind a wide variety of dry biomasses,

be low-cost and easy to build using mostly hand tools, easy to

operate, easy to maintain and require no welding.

The grinding process is

accomplished by rotating a concrete grinding head with its

aggregate exposed against a matching concrete grinding cup

with its aggregate exposed, and introducing biomass in

between the two surfaces. The grinding cup is supported with

two degrees of freedom in order to absorb the movement from

an out-of-round grinding head or the accidental introduction

of small stones or stick into the grinding space. The

grinding head is easily rotated using a hand crank at a slow

speed (under 90 rpm). The unit can be powered from a

bicycle, a foot powered treadle, a gasoline motor or an

electric motor. Grinding pressure is easily adjusted by the

weight of a few rocks in a pail. See the

Engineering For Change page E4C.

Biomass Chopper Thrasher

Portable Thrasher-Masher-Chopper

By the

Legacy Foundation

I recommend

you consider this new

design by Richard Stanley from the Legacy Foundation. Preparing biomass for

briquette production remains a crucial step in the briquetting process.

Richard has developed a very successful idea as described in

his new construction manual. The chopper was fine tuned and tested in rural

Guatemala and Nicaragua for three years)

Designing a low cost

grinder featuring ease of use, and easy to build, has been a challenge for

both Richard an me. We often

work closely together in a effort to bring you the best ideas possible. You

can contact Richard

HERE.

Biomass Chopper Cutter

How

To Build A Biomass Copper-Cutter Manual

600K PDF

Spanish Manual Version Here

Video describing the Wet-Dry Biomass Chopper Cutter

See Biomass Chopper by Joshua Guinto

Video test cutting prairie grass for a biogas project at the Cincinnati Zoo

The chopper/cutter was designed to cut both wet and dry

biomass. The chopper is easy to build using mostly hand tools, easy

to operate, easy to maintain and requires no welding. The

unit runs efficiently at a low crank speed and can be easily

operated by women or children. See the

Engineering For Change page E4

Virginia Tech has modified the original design to satisfy their needs:

Read Details Here

Biomass Composter

Biomass Composter

How

To Build A Biomass Composter

– Rotatable and Portable 2.6 MB, PDF

Spanish Manual Version

Using either a plastic or steel

drum you can easily fabricate a barrel composter for the aeration

of biomass

that is both rotatable and portable.

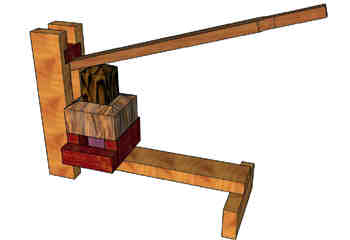

Large Compound-Lever Biomass Briquette Press

How To Build A Large

Compound-Lever Biomass Briquette Press

340K, PDF

This is the traditional large

compound lever press used all over the world, and works with molds diameters

from 3 inch to 6 inch.

Mold designs have greatly improved since the

original design of this press and we suggest downloading the

How To Build Biomass Molds.

See the compendium for a variety of biomass mold

suggestions.

Small Biomass Briquette Press

How To Build A Small Single-Lever Square Biomass Briquette Press

Manual

570K, PDF

If PVC is not available

or expensive in your area then the 3 inch square wood

mold could be an alternate.

Mold

designs have greatly improved since the original design of

this press and we suggest downloading:

How To Build Biomass Molds

for a variety of biomass mold suggestions. We

now have a better method for making a square briquette using

a wood mold.

How To Build A Small Biomass Briquette Press

English, 880K, PDF

How To Build A Small Biomass Briquette Press

French, 600K, PDF

Suggested for use as a

classroom demonstration briquetting press or where

construction resources are limited.

Mold

designs have greatly improved since the original design of

this press and we suggest downloading:

How To Build Biomass Molds.

See the compendium for a variety of biomass mold

suggestions.

The Legacy Foundation

Briquetting Video

by The Legacy Foundation

Briquetting Video

by The Legacy Foundation

Briquette Ratchet Press by The Legacy Foundation

Briquette Ratchet Press by The Legacy Foundation

If

you have not read the briquetting instructions available at the

Legacy foundation, I highly recommend reading them thoroughly prior

to starting a briquetting operation.

They also have several biomass

briquette presses made from metal. See them

HERE

The Legacy Foundation provides training, technology and

media services for biomass fuel briquette production, environmental

conservation and income generation throughout the world.

They have a number of excellent manuals on

briquetting. Visit them

HERE

Engineers Without Borders UK Sugar Cane Waste

Briquettes

Producing Fuel Briquettes from Sugarcane Waste

600K, PDF

By: Chesta Tiwari, Mechanical Engineering Department, University of Sheffield

Rice Husk Briquettes

Rice Husk Briquettes

Development of Rice Husk Briquettes for Use as a Fuel

80K, PDF

By: D.B. Yahaya and T.G. Lbrahim

Department of Mechanical Engineering, Bayero University, Kano

Cheese Press

Cheese Press

Adaptable as a Cheese Press as described by

this thread on the

CheeseForum.org

Compressed Earth Press

Compressed Earth Press

Adaptable as a Compressed Earth Block/Brick

Press (CEB) as described by Amedean Messan in this thread on Permies.com

Additional organizations have

built the press:

Joshua (Jed) Guinto from Philippines

Pix-1, Pix 2,

Video for Jed Guinto and Coastal

Core Sorsogon;

Instructables,

Permies.com

Fuel Briquettes from Banana Plant Waste

Feasibility of Biomass Fuel

Briquettes from Banana Plant Waste 2.7 MB,

PDF

Spanish Version Here

By Lee Hite and Dr. Zan Smith

Biomass Briquette Stoves

Biomass Briquette Stoves

See the

Stack-fed, Heat

Exchanger, Biomass Briquette Stove

by: Harold Westerich, Redwood City, CA

ALSO, see Norman Desrosiers,

and what he

has done

to heat his home.

download his

PowerPoint, 4 MB, pptx Norm has done a lot of experimenting and developed meaningful

enhancements to the process.

Keeping Elephants at Bay using Chilli Briquettes

Keeping Elephants at Bay using Chilli Briquettes

Burning

chilli will keep elephants at bay, new study finds

Simple and Easy Briquettes Without a Press

Simple and Easy Briquettes Without a Press

How to Make Fuel Briquettes Without a Press

By: Joyce Lockard rj.lockard@frontier.com

Fuel Briquette Team, Beaverton Rotary Club in OR, USA, 2

MB, PDF

Briquetting Resources

Additional Fuel Briquetting Info

The

Briquetting of Agricultural Waste for Fuel 515K, PDF

Biomass

Briquettes Turning Waste Into Energy 235K,

PDF

Briquetting and Stoves Groups

Fuel Briquetting Group

Biomass Stoves Group

TChar Technology

for Cookstoves

By: Paul Anderson, Christa Roth and

Robert

Fairchild

- Calculators and Converters

-

Calculator Edge

-

Convert World

Good

Calculators

Engineering Toolbox

< align="left">

-

Materials and Conversion

Metric-Conversions.org

(Multilingual)

Unit Converter

|

Caloric Value Of Raw

Materials |

|

Caloric Value Of

Fuel Materials |

| Raw Materials |

KCal / Kg |

|

Raw Materials |

KCal / Kg |

| Bagasse (sugar Cane) |

4,200 |

|

Arhar Stalk |

4,000 |

| Bamboo Dust |

3,700 |

|

White

Coal Briquette |

4,000 |

| Bark (wood) |

3,900 |

|

Char Coal |

6,000 |

| Castor Seed Shell |

4,000 |

|

Coal Grade 'B' |

5,000 |

| Coffee Husk |

4,200 |

|

Coal Grade 'C' |

4,000 |

| Coir Pitch |

4,000 |

|

Diesel |

9,400 |

| Cotton Stalk |

3,800 |

|

Fire Wood |

3,300 |

| Ground Nut Shell |

4,000 |

|

Heavy Furnace Oil |

9,900 |

| Jute Waste |

4,500 |

|

Kerosene |

8,900 |

| Maize Stalks |

3,800 |

|

Lpg |

9,400 |

| Mustard Husk |

4,500 |

|

Saw Dust |

4,000 |

| Pine Needles |

4,000 |

|

Sugar Cane Trash |

3,500 |

| Rice Husk |

3,500 |

|

Sugar Mill Waste |

3,300 |

| Rice Straw |

3,500 |

|

Wheat Straw |

3,700 |

| Sar Khanda Grass |

3,700 |

|

|

|

|

Source

www.biomassbriquetting.com/briquetting-plant-india.php |

We provide designs on this web site as "open source" but we do ask

that credit and a link be provided back to this site. Thank you.

About me: I am a retired electronics engineer with a passion for

investigating technical issues, occasionally surrounded with mystery and

often bridging several fields of technology. About me: I am a retired electronics engineer with a passion for

investigating technical issues, occasionally surrounded with mystery and

often bridging several fields of technology.

HOME | CHIME

DESIGN

Old Ham Radio Call

Books -

Cincinnati

Triple Steam -

Nuclear

Aircraft -

Emergency Medical

Leland Hite (Lee) K8CLI

www.leehite.org

All Rights Reserved

|